THERE ARE SOME pairings that take no thought at all. If someone asked you to say the first thing that came to your mind after the words “peanut butter,” odds are you would immediately reply, “jelly.” Along those same lines, if someone said, “citrus, ”you more than likely would reply, “Sunshine State,” or if someone said, “Plant City,” the word “strawberries” might instantly be brought to the forefront of your mind. However, in the world of agriculture, it is taking energy, effort, and a lot of time for growers on the cutting-edge of their industries to show the world how farm technology and environmental stewardship are a powerful pairing that goes hand-in-hand.

A poster child for one such longtime effort would be Florida Blue Farms, Inc., which was recently one of three Florida farms to be awarded the 2017Commissioner’s Agricultural Environmental Leadership Award. For over eight years, the Lee family has been farming in Waldo, Florida, with an emphasis on environmental stewardship. In 2009, the family began the work of converting 110 acres of their silviculture land into a Southern Highbush Blueberry farm. Since then they have expanded to 90 acres of current production. We had the opportunity to talk to Brittany H. Lee about some of the technology currently in use on the farm, and she has an interesting story to tell.

TECH FOR THE WATER

Once all the heavy work of removing pine trees and their root systems was completed, the Lee farm worked on making sure the drainage for water was suitable for the new blueberry fields. The slope of the land has a 40-45 foot drop from the front of the property to the back, which meant a lot of water potentially traveling through the property at certain times of the year. A two-acre tailwater pond was installed to capture and reuse runoff. “The original intention of the design was put in place so that eventually we could recapture water and reuse it, and that is something that we did start doing back in 2015with the installation of a tailwater recovery pond to actually catch the water,” Lee explains. The goal was to reduce the amount of groundwater pulled out for frost/freeze irrigation purposes by 50 percent. The farm is well on its way to meeting that goal, with a reduction of 40 percent last year, and an expected 50percent for this year.

Three pumps are used to pull water from the pond, supplementing the existing three deepwater wells, and feed it into the overhead irrigation system, which is used to protect against freezes in the winter months. When Florida’s freezing temperatures strike, blueberries require 0.3 inches of water per hour to properly shield against freeze damage.

TECH ON THE GROUND

One interesting feature of Florida Blue Farms is their use of EnviroGrid Geocell System to preserve the grade of land on which heavy machinery and trucks are moved through the property. It consists of a heavy-duty plastic honeycomb over a ground cloth, then filled with granite gravel. This type of ground preservation is used in areas such as the creek bed in order to allow a natural flow of water despite being traversed by farm vehicles.

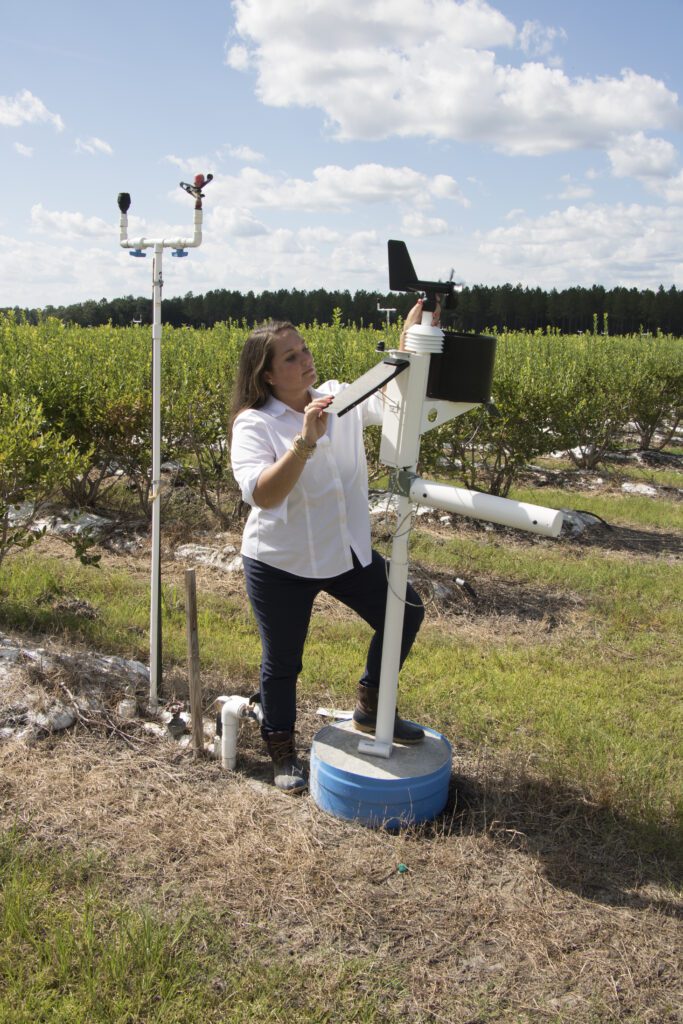

Soil monitoring is performed through a combination of traditional monitoring tools: implants in the ground (which must be visited and checked by hand), and more modern weather stations that provide remote access to moisture data. Six such weather stations are positioned throughout the property, which can have up to four soil-monitoring sensors attached. Monitoring probes are attached to the weather stations by 50- or 100-foot cords and can be placed in the ground wherever you want to collect data from. Soil and tissue samples are collected throughout the year for lab analysis as well.

The RainWise weather stations used on Florida Blue Farms also collect information on temperature, humidity, wet bulb, wind, and dew point. One is acellular station and the other five are Wi-Fi with a strong radio antenna. This makes it possible to monitor weather data from anywhere you have Internet access. Two other recently installed Metos stations read dry temperatures and wet bulb temperatures. There are also several other backup, portable systems in use on the farm, such as the highly accurate Verigo pod system, which is a Blue tooth device used to verify weather information throughout the property. Old-fashioned orchard thermometers are still in place throughout the farm, though those are rarely used these days, due to the efficiency and ease of more modern technology. For ground cover, DeWitt Sunbelt Woven Ground Cover is used. is a polypropylene fabric used to conserve water and control weeds.

TECH IN THE AIR

Another example of the use of cutting-edge technology on the farm is the use of aerial drones to monitor plant health. is service is provided through the Highland Precision Ag program, which is also used to track the data acquired from the tissue and soil samples. e information collected by this program is used to inform the growers about real-time conditions in order to optimize production. It is a method of monitoring known as “precision agriculture,” (PA) also called “satellite farming” or “site-specific crop management”(SSCM).But why go through all this e ort to surround the farm top-to-bottom with the latest tools available? Like most questions worth answering, there are several reasons. For one, crop protection materials and production costs can be minimized with efficient utilization of these tools and practices. e upfront cost of the technology is easily justified by the long-term benefits, including a reduction in man-hours. Being able to detect pests or disease earlier can reduce losses. “ Here are of course costs associated with implementing these technologies,” Brittany says. “The cost is more than offset by the efficiency or being able to use less man-hours. In the long run, the technology pays for itself.” Another more obvious reason is that it can help maximize yields— a crop under less environmental stress will (with optimal conditions) produce more yields. But perhaps the less obvious, and most important reason, is that it brings us back to the powerful pairing we see at Florida Blue Farms— the latest farm tech and environmental responsibility— which aids in conserving our natural resources.

Moving into the future, Florida Blue Farms is equipped to meet the demands of the modern consumer and continue growing. “Right now, we’re at 110 acres. As we look toward the future, we have the opportunity to expand to 146 acres,” Brittany says. “My long-term goal for the farm is to provide a legacy for my children and my siblings’ children and continue with this family farm for many more generations.

story by TERESA SCHIFFER

photos courtesy of the FLORIDA DEPARTMENT OF AGRICULTURE AND CONSUMER SERVICES